AVIX SUITE

Process Lean Tools in one package

PRODUCTION AND PROCESS OPTIMIZATION

In today’s fast-paced and complex world, companies face constant changes and increasing demands for agility. To stay competitive, businesses must optimize their production engineering processes and improve efficiency across a range of critical areas, from production optimization to product development and producibility. That’s where AVIX comes in – our powerful process mapping tool is designed to help companies improve profitability by streamlining their workflows and increasing efficiency.

For companies already working with Lean Production and lean manufacturing tools such as 5S, Kaizen, SMED and standardized work, the challenge lies in maintaining “technical productivity” – the administrative and time-consuming task of keeping all methods, tools, and documents organized. With limited resources in engineering departments, this task can be particularly challenging. But with AVIX, you can simplify your processes and free up your engineering team to focus on the important work of driving innovation and growth.

Experience the benefits of AVIX today and join the growing number of businesses that are maximizing their efficiency, productivity, and profitability with our innovative software solutions.

This is why manufacturing companies world-wide uses AVIX for Method- and time studies, Line balancing, FMEA, SMED, Work instructions and DFA. But foremost, AVIX has helped hundreds of companies with their lean process improvement.

We call it production engineering efficiency!

AVIX ModuLES

Method

Increase the productivity in your processes, using the latest technology.

Resource Balance

Increase productivity and efficiency in your production line.

FMEA

Control your process and increase productivity with fewer stops.

SMED

Reduce set-up time and produce more.

DFX

Effective product development and greater manufacturability.

ERGO

Visual Ergonomics for improved working conditions.

- Production improvements – The details from the AVIX analysis makes it easy and visual to show process improvement potential and problems.

- Reduced time spent on updating data – All data is linked together in AVIX. A change in assembly sequence immediately effects e.g the work instruction.

- Do more in less time – When analyzing in AVIX you’re not just creating a time study, at the same time you create data for line balancing and work instructions.

This is AVIX

Method

- Intuitive process mapping tool

- Automated workflows and process routing

- Multilanguage support

- Process times from stopwatch, MTM, SAM etc.

Resource Balance

- Manage product variations

- Create product mixes

- Balance based on orders

- Simplified production planning and scheduling

- Advanced analytics and performance metrics

- Reports and data analysis tools

FMEA

- D-FMEA & P-FMEA

- Automatic control plan

- Customizable FMEA template

- AIAG & VDA template

- Streamlined risk management processes

ERGO

- Analysis per work station and process

- Borg CR-10

- ErgoSAM

- Easy-to-use ergonomics analysis tools

SMED

- Reduce set-up times

- Manage multiple operators

- Minimize downtime

- Suitable for service operations

- Streamlined set-up planning and execution processes.

DFX

- Design for assembly

- Discover design issues early

- DFA/DFA2

- Standardize producibility methodology

- Streamlined product design and development processes.

GENERATE OUTPUT

- Resetting instructions

- Work instructions

- Parts & tools

- Action reports

- Multilanguage support

- PDF, XLSX, DOCX, PPTX documents

- XML/data export

- Web based

- Movie instructions

Software support

AVIX is way of collecting all data for e.g. method and time studies, line balancing and FMEA in one and the same place. That makes it much easier to administrate and keep the data updated. But foremost is it a much easier and effective way compared to creating the time study using pen and paper, a work instruction in Word and a BOM from Excel. AVIX can also easily exchange information with other systems using XML-format.

A CLOSED LOOP

The information in AviX is linked together. Changing the method study for a workstation will immediately affect the line balance and the work instruction (SOP). This is a huge advantage since it simplifies the most common problem for the production engineering department: Keeping the information updated and correct. Otherwise there is a big risk that data will be obsolete and outdated, and everybody looses confidence in work instructions and documentation. We call it production engineering efficiency!

IT IS EASY!

It is easy! AVIX is well known for being intuitive and easy to use, we know that from hundreds of users. It only takes roughly a day of training to learn the basics in AVIX and get going, but most users can use AVIX just from the experience during a pilot project.

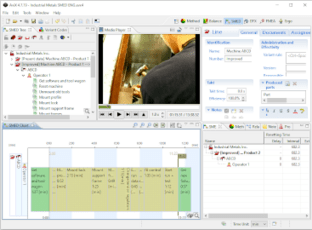

STEP 1

VIDEO RECORD THE PROCESS

We start with a movie, break it down into a work sequence and immediately we have the data needed for the method study (std. work), line balance and work instruction (SOP).

STEP 3

CREATE WORK INSTRUCTION

From the structure in AviX, we can now print a work instruction (SOP), more or less detailed, eg. with or without pictures. It is also possible to print a unique work instruction for each product variant.

COMPANY

- One Standard!

- Reduced losses

- Increased flexibility

- Standardized methods

- Production costs

- Decisions based on facts

- Resource Planning

ENGINEERING

- Powerful and efficient tool

- Enhancements vs. current situation (simulation)

- Structured way of working

OPERATOR

- Work environment, ability to influence the work

- Communication

- Training

- Insight and understanding of the processes

SALES

- Cost calculations

- Flexibility when changes occur

CONTACT US FOR A WEB-MEETING OR VISIT

Let’s us show how AVIX can support your process improvements